TECHNICAL

Photo-mask related products (Mask production systems we can supply)

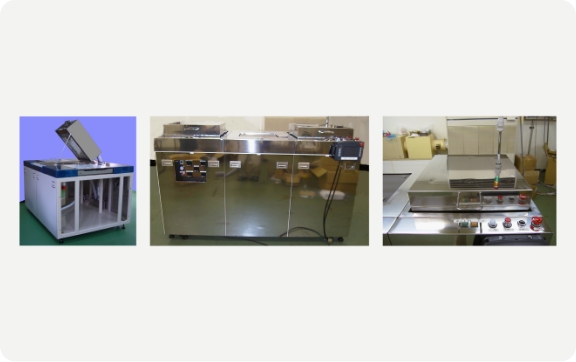

Mask Cleaner

- Ultra sonic, mega sonic cleaning

- Strong Asid, Strong Alkaline cleaning

- Detergent, Brush cleaning, tec.

Photo-Resist Coat

- Spin coat for Mask:4, 5, 6, 7” blanks

- Large mask Spin coat:G2∼G6 Mask size

- Slit coater:G2~G6 FPD Glass plates

HP/CP・Baking

- HP/CP:Plate type (~200℃±0.5%)

- Work size:5~7” for Mask/~G6 for FPD

Mask Writer

- Laser Writer for LSI mask(~65nm T-node)

- Laser Writer for FPD mask(~ G10 mask)

- Laser Direct Image for Package(~1μmCD)

Wet Process Batch/Single type

- Developing :Spin/Dipping/Shower type

- Etching :Spin /Shower type

- Stripping :Spin/Dipping/Shower type

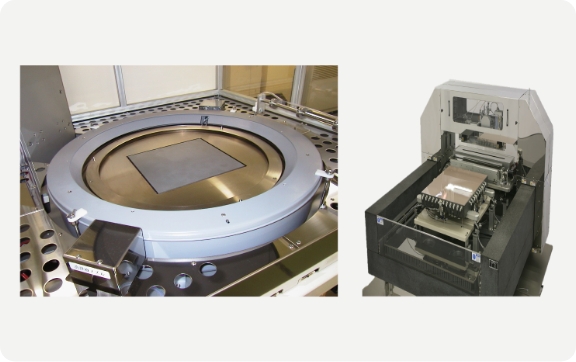

Inspection

- Registration for LSI mask&FPD mask

- CD measurement:0.5umCD, 1nm Accuracy

Mask Repair

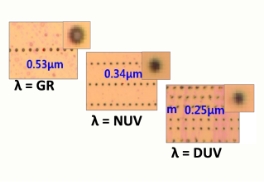

- ZAP repair:0.5μm size, 50nm accuracy

- CVD repair:2μmsize, High throughput

- HT-CVD:5%~50% transmittance

Mask Writing technology(Pattern generator by Laser)

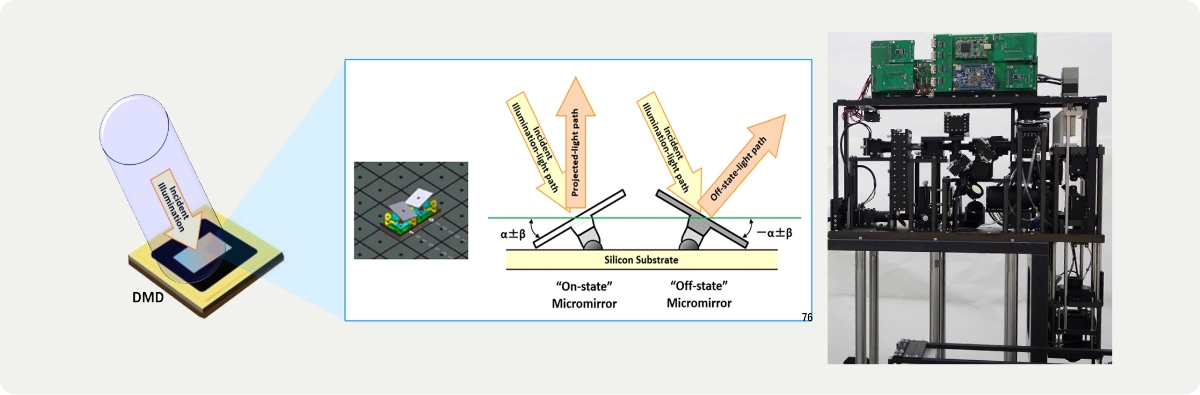

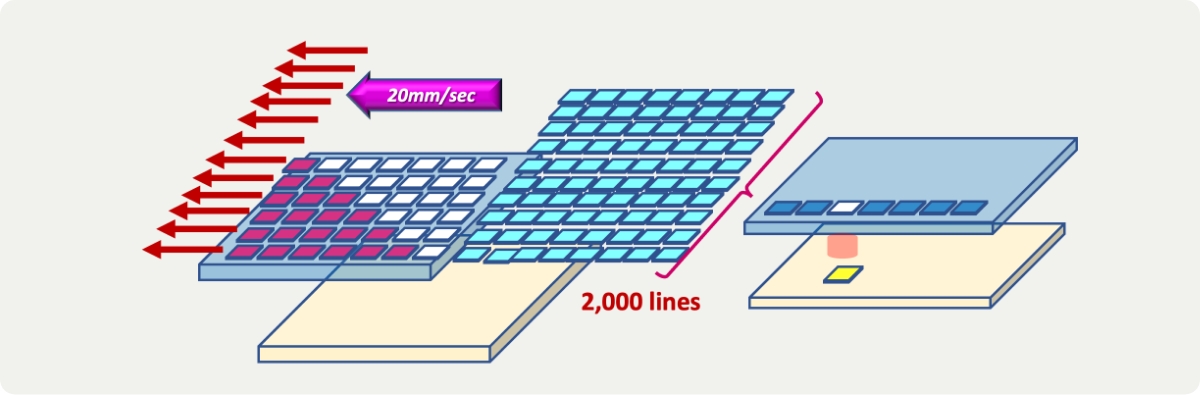

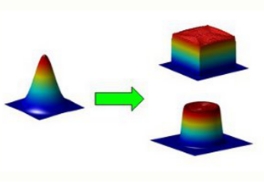

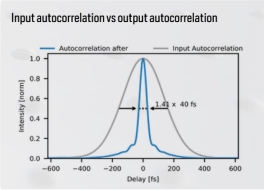

Artfil developed the Photo-mask Writer by using DMD, which is quite State of the art technology. Specially the Writing principle is very unique for Dose control by applying digital & quantitively adjustment function. It create a very stable control for CD uniformity, Linearity, OPC and Mura performance.

DMD device has many elements and each element can be on/off of irradiation independently. 256 elements shot the light at the same place, the integrated exposures of 256 shots generate 100% dose. So, the dose adjustment is done by each one shot dose, which is called BSI( Binary Shot Integration). This technology gives a very stable exposure performance with such digital CD control.

Mask Repair technology(Repair by using Laser)

COWIN(Korea) is the leading edge company for Laser Repairing technology and developing High performance repair system by using Precise beam control functions for LSI Photo-mask application.(as shown below.)

| 2022 | 2023 | 2024 | 2025 |

|---|---|---|---|

| Zap性能 0.7μm |

0.7μm (130mm) |

≦0.7μm (90mm) |

~0.18μm (45mm) |

| CVD性能 3μm |

2μm | 1μm | 0.5μm |

|

|

|

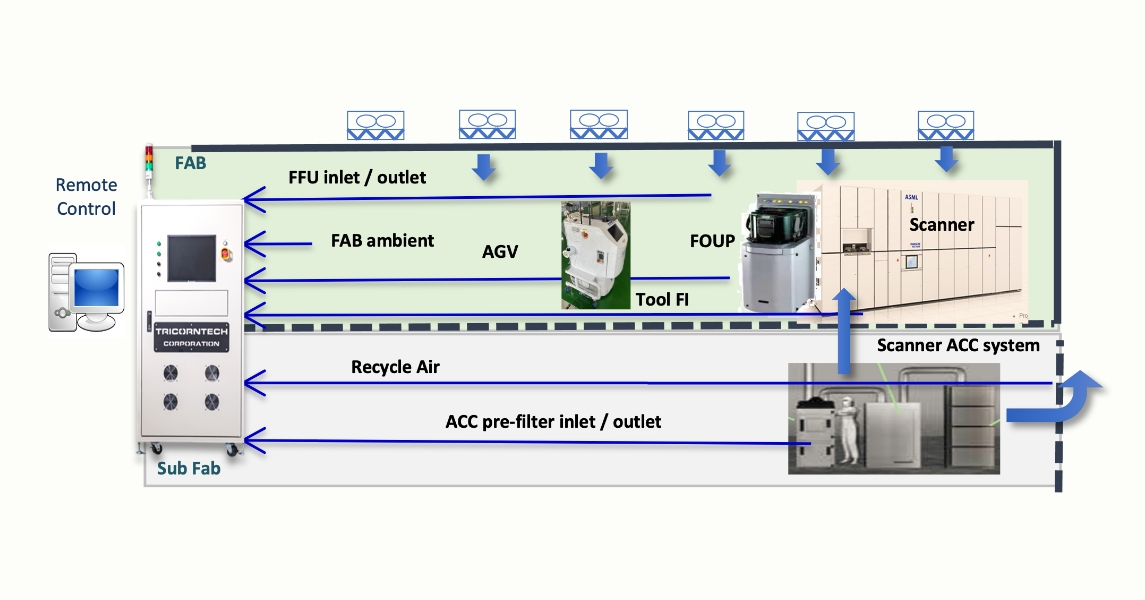

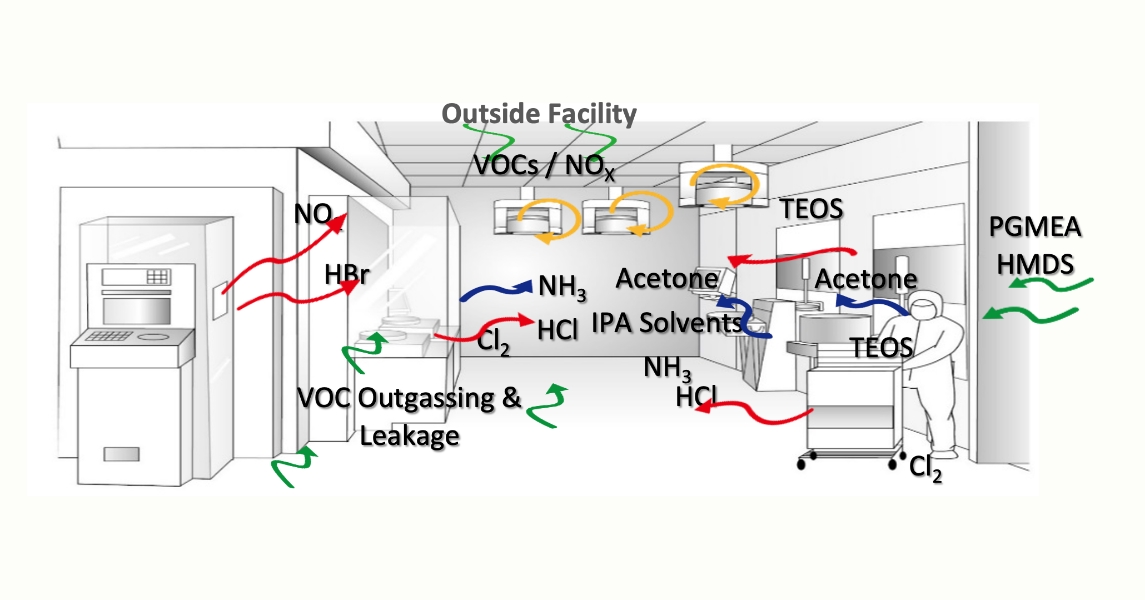

AMC Monitor technology

Needs AMC Monitor technology for High-end Lithography Process

There are many chemical materials and contaminations like AMC which exert bad influence to Photo Lithography and Exposure machines in Semiconductor production process. So, such AMC monitor & management are very important and issue in the semiconductor production area.

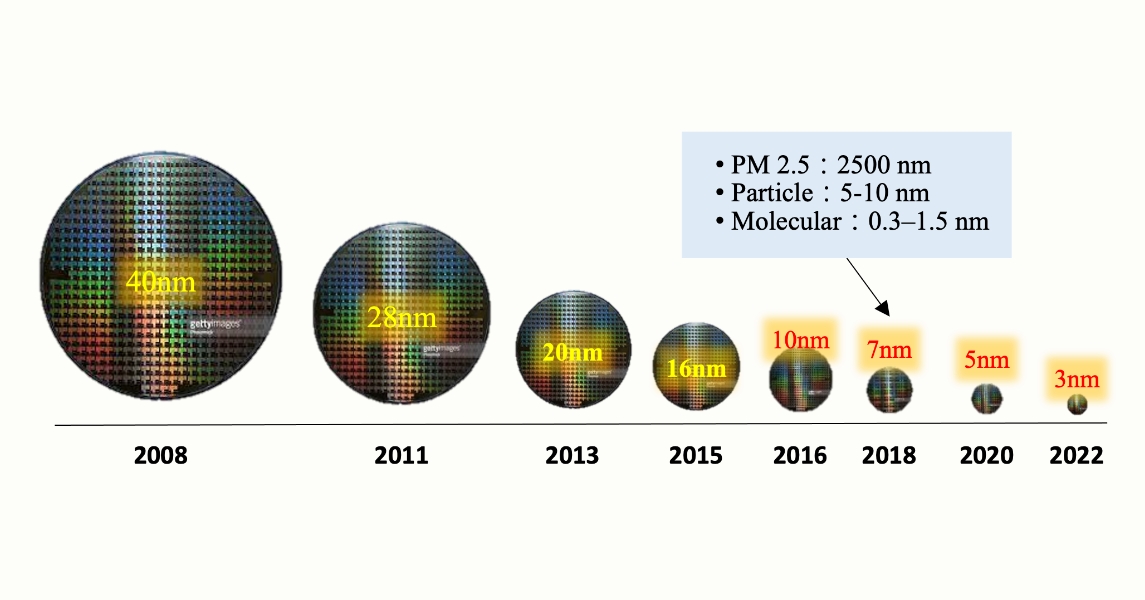

MAC monitoring is required to avoid making Defect, Excursion, Haze and etc. under the below technical node of 28nm process. Because this solution leads to improvement of product yield surely.

AMC Monitor systems made by Tricorntech have already been contributing in many Semiconductor production factories. The systems can monitor AMC with high performance of 0.1ppb level at real time in FAB & Sub-FAB.